Zinc alloy die casting is a highly efficient manufacturing process that produces precision metal components by injecting molten zinc alloy into a steel mold under high pressure. Due to zinc's excellent fluidity, low melting point (around 385°C), and superior mechanical properties, this method is widely used in industries such as automotive, electronics, hardware, and consumer products. Compared to aluminum and magnesium die casting, zinc alloy die casting offers better dimensional stability, smoother surface finishes, and the ability to produce intricate thin-walled parts with tight tolerances.

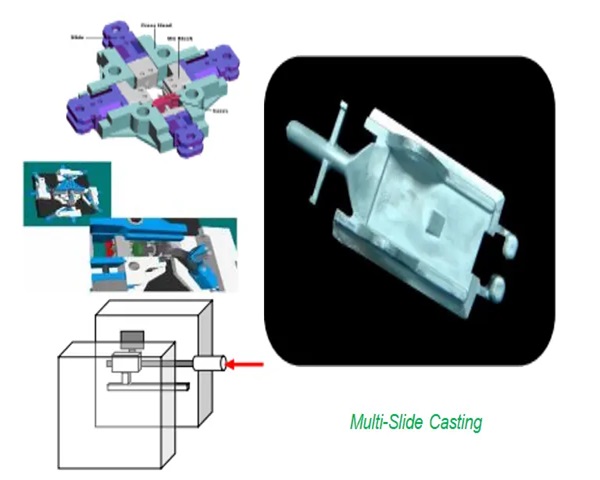

The process relies on high-pressure injection to rapidly fill a die cavity with molten zinc alloy. Key steps include:

Melting & Alloy Preparation – Zinc alloys, most commonly Zamak (Zn-Al-Cu-Mg), are melted in a furnace at controlled temperatures (400-430°C) to prevent excessive oxidation.

2Injection – The molten alloy is forced into the die cavity at pressures ranging from 200 to 1,000 bar, ensuring complete mold filling before solidification.

Cooling & Ejection – After solidification (typically 5-20 seconds), the component is ejected, and excess material (flash) is trimmed.

Post-Processing – Secondary operations such as machining, plating, or powder coating enhance functionality and appearance.

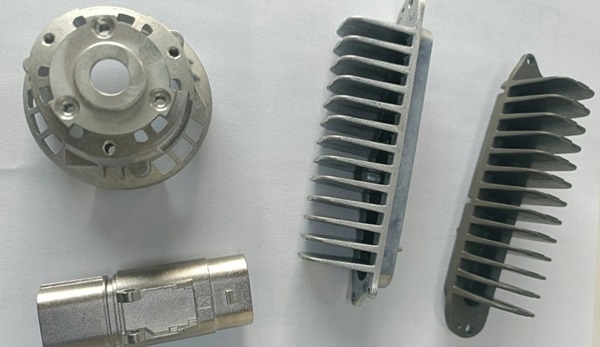

This cycle enables high-volume production with minimal material waste, making zinc alloy die casting ideal for complex geometries like gears, housings, and connectors.

Property | Zinc Alloy | Aluminum Alloy | Magnesium Alloy |

Melting Point | ~385°C | ~660°C | ~650°C |

Fluidity | Excellent | Good | Moderate |

Strength-to-Weight | Moderate | High | Very High |

Surface Finish | Very Smooth | Good | Fair |

Machinability | Excellent | Good | Moderate |

Cost | Low-Medium | Medium-High | High |

Zinc alloys outperform aluminum and magnesium in terms of mold life, surface detail, and cost-efficiency for small to medium-sized parts. However, aluminum and magnesium are preferred for ultra-lightweight or high-strength applications.

To ensure optimal results in zinc alloy die casting, manufacturers must adhere to strict operational guidelines:

Temperature Control

Maintaining proper melt temperature (400-430°C) prevents premature solidification and ensures smooth metal flow. Overheating can lead to excess dross formation and reduced alloy integrity.

Die Lubrication & Cooling

Applying the right type and amount of die lubricant prevents sticking while ensuring efficient heat dissipation. Uneven cooling can cause warping or internal stresses.

Injection Speed & Pressure

Too much pressure may induce porosity, while insufficient pressure leads to incomplete filling. A balanced injection profile (fast fill, followed by controlled solidification) is crucial.

Material Purity & Alloy Composition

Even small impurities (Pb, Fe) can degrade performance. High-purity zinc (Zamak 3 or 5) ensures durability and corrosion resistance.

Post-Cast Handling

Avoid abrupt quenching, as rapid cooling may stress components. Proper trimming, deburring, and finishing prevent defects in final products.

Several issues can arise during zinc alloy die casting, each requiring specific corrective actions:

Porosity

Caused by entrapped air or gas bubbles. Solutions include optimizing injection speed and venting design.

Flash

Excessive material leakage between mold halves indicates poor clamping force or die wear. Tightening tolerances or replacing worn dies resolves this.

Cold Shuts

Incomplete fusion of molten streams due to low temperature or slow injection. Raising melt temperature or increasing fill speed helps.

Soldering

Zinc sticking to the die surface, often due to inadequate lubrication. Applying proper die coatings reduces adhesion.

By implementing strict process controls and regular die maintenance, manufacturers can minimize scrap rates and improve product consistency.

As industries demand lighter, stronger, and more complex components, zinc alloy die casting remains a cost-effective solution for high-quality metal parts. With proper temperature management, pressure control, and alloy selection, manufacturers can achieve superior mechanical properties, fine surface finishes, and extended tool life—making zinc die casting an essential process in modern manufacturing.