Zinc die casting serves as a vital process in modern manufacturing, particularly within the automotive and broader industrial sectors. It is highly regarded for delivering precision, durability, and cost-effective production of complex components that require strength, attractive finishes, and precise tolerances.

The zinc die casting process entails injecting molten zinc alloys at high pressure into durable steel molds, known as dies. After cooling, the resulting parts exhibit outstanding dimensional accuracy and smooth surface quality, typically needing only minimal additional machining or finishing. This streamlined approach often makes zinc die casting more advantageous than alternatives such as machining from solid stock, stamping, or assembling separate pieces. Among non-ferrous options for die casting, zinc excels due to its blend of high strength and hardness for enduring performance, strong corrosion resistance to withstand demanding environments, excellent electrical conductivity suited for electronic applications, and the capability to form intricate, near-net-shape parts that minimize waste and reduce the need for assembly.

Zinc die casting has long been intertwined with automotive advancements, as many process improvements stemmed from the industry's push for lighter, more robust, and economical components. Contemporary vehicles depend extensively on zinc die-cast parts to enhance safety, dependability, and design versatility. Zinc enables engineers to develop compact, multifunctional designs that maintain structural integrity while cutting weight and costs through integrated features. With its exceptional strength, corrosion resistance, and dimensional stability, zinc supports both functional under-hood elements and visually refined interior details, helping shape efficient and appealing automotive production.

Automotive interiors prioritize both visual appeal and user comfort, areas where zinc die casting delivers significant advantages. Parts like door handles, knobs, gear-shift surrounds, and various decorative trim pieces are commonly produced using zinc alloys. These components feature smooth, high-quality finishes that convey a premium feel and resist wear over time, helping maintain the cabin's attractiveness. Zinc's superior castability further allows for elaborate shapes and surface textures that complement brand styling, seamlessly blending practicality with sophisticated design.

In the engine compartment, where components face extreme conditions, zinc die casting provides reliable solutions for items such as mounting brackets, housings, covers, and connectors. Zinc's elevated melting point and mechanical stability enable these parts to resist heat, vibration, and fluid exposure effectively. Its favorable strength-to-weight ratio and inherent corrosion protection often allow zinc castings to supplant heavier or costlier fabricated alternatives.

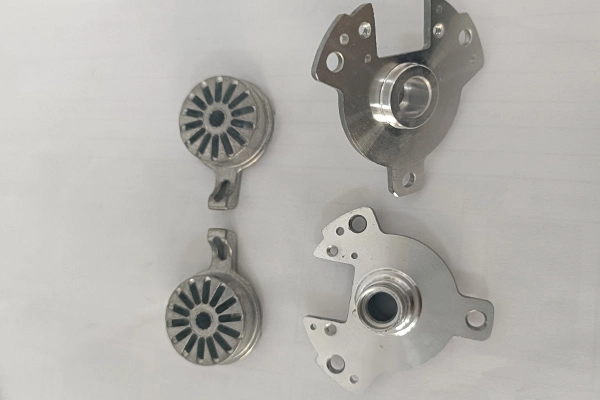

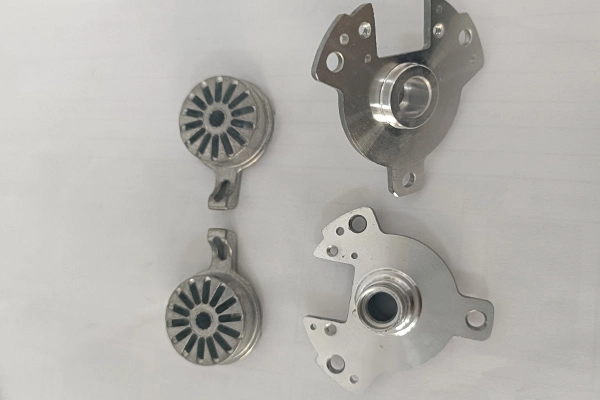

Precision and reliability are essential in modern power steering assemblies to support safe and effortless vehicle control. Zinc die casting facilitates the creation of pump housings, gear housings, and connector fittings with exceptional accuracy at the micron level. The material's density and strength effectively manage hydraulic pressures, delivering sustained performance even under heavy use.

Braking systems require components capable of handling intense stress and temperature variations. Zinc die-cast elements, including pistons, actuators, and housings, offer the necessary toughness combined with stable dimensions. Tight tolerances achieved through this process promote reliable sealing and consistent operation, which are crucial for safety and meeting strict regulations.

Climate control systems in vehicles incorporate zinc die-cast parts such as compressor elements, valves, and housing connectors. These endure repeated pressure changes and thermal cycles, where zinc's corrosion resistance and thermal characteristics contribute to extended service life. The alloy's excellent fluidity during casting supports the formation of detailed internal passages and fittings in compact designs, which is especially valuable for advanced HVAC configurations.

Fuel system parts require precise engineering alongside resistance to chemical exposure. Zinc die casting produces durable nozzles, connectors, and pump housings with fine details and strong protection against fuel-related corrosion. This enhances overall system efficiency, minimizes potential leaks, and ensures consistent quality across high-volume production to satisfy performance and environmental requirements.

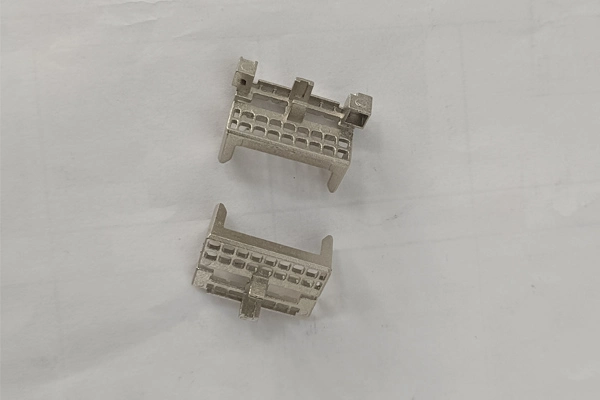

A major benefit of zinc die casting lies in its capacity to create near-net-shape components that demand little post-machining. Such housings act as protective enclosures for mechanical or electronic assemblies, incorporating built-in features like mounting points and threads. This approach reduces production time, material usage, and assembly expenses, leading to more streamlined manufacturing.

With vehicles incorporating more electronics, zinc die casting offers dependable options for sensor housings, control module enclosures, and connectors. Its strong electrical conductivity and EMI shielding properties safeguard sensitive circuits effectively. Moreover, the process yields fine surface quality and tight precision, suiting both hidden internal parts and visible elements like switches or covers.